- #CENTROID CNC SOFTWARE INSTALL#

- #CENTROID CNC SOFTWARE SOFTWARE#

- #CENTROID CNC SOFTWARE PC#

- #CENTROID CNC SOFTWARE PLUS#

- #CENTROID CNC SOFTWARE PROFESSIONAL#

#CENTROID CNC SOFTWARE SOFTWARE#

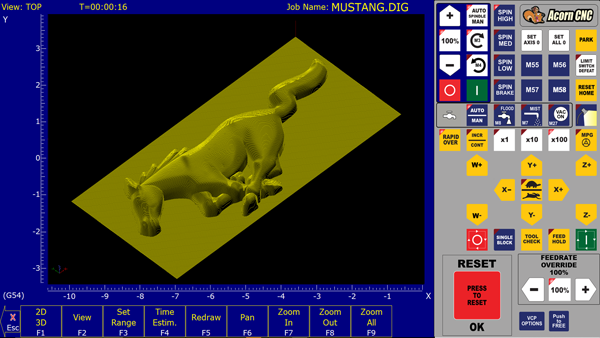

I use for my cnc activities, the products developped by centroidcnc : Ĭentroidcnc has developped a controller card named ACORN :Īnd ACORN Mill and Lathe CNC12 software for use with the Centroid Acorn CNC controller Click on the link to down load the appropriate document.Unofficial cnc_centroid_skinning - A wrapper to the CNC12 API language. Let us quote the right control for your specific machine application.Ĭontact us or Call us toll free at (877) 733-5500 We have developed a Request a Quote worksheet that outlines the information needed for us to provide you with a budgetary quotation. Either system can be wired to control your existing spindle VFD or CW/ CCW magnetic contactors.

#CENTROID CNC SOFTWARE INSTALL#

Install it yourself or, for an additional amount, have it professionally installed by Machines in Motion Inc. Remember these are base prices for the hardware & software.

#CENTROID CNC SOFTWARE PC#

You (or us) supply the PC computer, monitor, and keyboard. You retain your existing DC servo motors (up to 40"/lbs.) & encoders. Lower cost control retaining your current servo motorsĬentroid's latest Allin1 CNC control system comes packaged in a wired electrical enclosure with PLC and 3 axis of DC servo power. Your cost for this 3 axis control package is 12,500.00. MPU11/M-400S control system includes everything from the control console and keyboard to the servo motors and encoders. There are many new features that have been added to an already impressive product. This latest MPU11 hardware set is their most advanced controller ever produced. Now you are ready to start cutting metal, rock, wood, or whatever materials your business is involved in. Once the hardware is mounted and wired there will be about 30 minutes of parameter settings to be configured. Labeled cables will extend from the enclosure to reach each of the devices listed above. Typically consisting of your axis limit switches, spindle motor, VFD, Lube pump, and flood or spray mist coolants. Others will need adaptor plates and or shaft adaptors.ĭ. In some cases your new motors will mount identically. Mount the new servo motors in place of the OEM motors. If your machine lacks a good mounting location Centroid offers an optional floor stand with casters.Ĭ. Remove the old enclosure and mount your new electrical enclosure.

#CENTROID CNC SOFTWARE PROFESSIONAL#

Install the mounting arm onto your machine then mount the professional control console.ī. Each of these 2 control configurations is completely wired and ready to be used.Ī. The second pre-built control system is wired for communication with most VFD type spindle speed controller.Ĥ. One has a set of reversing contactors used when CW/CCW spindle control is all that is required. Centroid builds 2 variations of their pre-built control. offers Custom PLC programming service if needed.ģ. There are additional inputs available for machine specific devices. This standard PLC is already programmed and installed in the control software. The 16 inputs are pre-configured for X Y Z limit switches, Low lube sensor, E-Stop switch condition, Spindle fault.

#CENTROID CNC SOFTWARE PLUS#

The PLC has 9 Relay outputs configured for Lube power, flood coolant, spray mist power, Spindle control, plus a few extra outputs. Digital encoders are installed and each motor has 14’ of power & encoder cabling.Ģ. 3 new DC servo motors at 29”/lbs in size. Either CW/CCW spindle contactors or wiring configured to control your choice of VFD. The only choice offered is for spindle control. The Centroid pre-built control provides 3 axis of servo motion (3 new DC servo motors), Professional CNC concole, and standard PLC programming. I have seen 3 different spindle motors on the same model Hardinge CHNC lathe and the same holds true for milling machines, routers, water jet cutters etc.įor knee mills and smaller sized bed mills the control configuration is so close that Centroid offers a single, pre-built, control system to fit this class of 3 axis machine tool.

So, one Mori Seiki SL2 is built with a 6 station turret the next is built with an 8 station turret. Machinery dealers and customers will order new machinery to suite their current needs. Even within the same make and model number there will be differences.

The first thing to know about Plug and play upgrades "They don’t exist." There are no universal standards in the machine tool building industry.

0 kommentar(er)

0 kommentar(er)